by James C. Sherlock

Among the things that the Russian invasion of Ukraine has made clear is the vulnerability of Taiwan and with it, the access of the U.S. economy to the 90% of advanced computer chips manufactured there.

The national security requirement for domestic chip manufacturing brings opportunity. It is the nation’s most urgent manufacturing priority. So, why not build the needed plants in Virginia? Is the Commonwealth organized to attract those investments?

For the answer to the last question I looked at the Virginia Department of Commerce and Industry, the State Council on Higher Education in Virginia (SCHEV) and Virginia’s engineering schools and found nothing to suggest Virginia is making an organized effort.

Much of Virginia’s headline effort in engineering education is to expand opportunities for Amazon workers in Northern Virginia.

I suggest Virginia focus its Department of Commerce and Trade on chip manufacturing, create dedicated educational consortiums, identify available facilities and workforces like those of the shuttered Rolls Royce plant in Prince George County and offer tax abatement packages to actively recruit semiconductor manufacture.

Virginia’s congressional delegation is pushing to make the state a national hub of semiconductor research. It is focusing on Henrico and Chesterfield as a potential location of a federally financed National Semiconductor Technology Center and National Advance Packaging Manufacturing Program.

I hope we get it.

But that is not chip fabrication. Virginia has no organized program that I have been able to find at the Department of Labor and Industry, among its universities or regional consortia to attract chip manufacturers.

Workforce composition. The controlling resources needed for chip foundries are educated and trained personnel.

You may know that Intel is making a huge investment in semiconductor plants in central Ohio. To discover what the work force must look like I consulted an article by the local NBC affiliate’s Columbus Business First.

About half of the jobs that initially come to Intel’s future semiconductor manufacturing factories in New Albany may only require a high school diploma, a sign that a wide swath of Central Ohio’s workforce may find that a job at Intel is within reach.

Another 40% of the jobs directly hired by Intel may require bachelor’s degrees, according to an analysis of the employment distribution at semiconductor manufacturing plants using U.S. Bureau of Labor Statistics data.

Intel is anticipated to employ 3,000 workers directly as a part of its initial $20 billion expansion to Central Ohio, though the project may eventually get much bigger as Intel builds more factories, or “fabs,” here. Those jobs will come with an average salary of $135,000, 2.5 times Columbus’ median household income.

According to BLS data, nearly 50% of the occupations that typically make up U.S. semiconductor manufacturing plants require only high school diplomas. The biggest group of those workers are likely to be electrical and electromechanical assemblers, followed by semiconductor processing technicians, inspectors and testers, as well as assemblers and fabricators.

The 40% of a semiconductor manufacturing plant’s workforce that requires bachelor’s degrees includes industrial engineers, software developers, electronics engineers, computer hardware engineers and electrical engineers.

The remaining 10% or so of the typical semiconductor manufacturing workforce is scattered between 7% of workers with associate’s degrees, and smaller chunks with no formal education, postsecondary non-degree credentials and some college or no degree.

Current chip plants in Virginia.

Virginia currently has only a few fabrication plants.

There are two Micron facilities in Manassas, and privately-held Virginia Semiconductor Inc. builds chips in Fredericksburg. Micron has announced plans to invest more than $150 billion globally over the next decade in leading-edge manufacturing and R&D, including potential fab expansion in the United States.

In 1998, Motorola halted construction of a $3 billion plant in Richmond just after it was started.

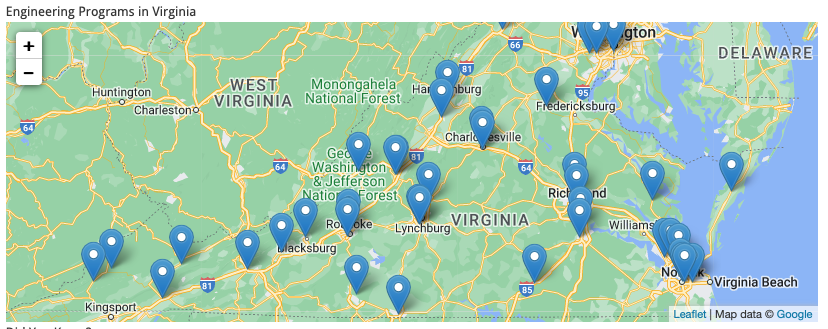

What to do? Virginia, in order to compete for the exploding demand for semiconductor fabrication plants in the U.S., must combine the ability to provide and continually update an educated workforce. That means a combination of engineering schools and community colleges. Virginia’s engineering programs include (see illustration)

- Engineering schools in Virginia: 47

- Undergraduate engineering programs: 42

- Graduate engineering programs: 16

- Schools with on-campus housing: 15

The geographic dispersion of those college programs, like our community colleges, distributes the opportunities widely across the state.

As an example of what might be done, the University of Virginia School of Engineering

… partnered with the construction industry to 1) expand course offerings; 2) increase exposure to the latest in CEM technology; 3) bring more practicing professionals into our classrooms; 4) connect students directly with career opportunities; and 5) create opportunities for training and coaching students for construction competitions.

The Virginia Department of Commerce and Trade has initiatives in broadband, energy and workforce development. Its efforts in manufacturing are focused on advanced materials, aerospace, automotive and wood products. Those are important industries, but are not exploding opportunities like chip manufacturing.

The Commonwealth will also have to compete in the tax abatement contests that accompany the quests for such investments. The states far ahead of Virginia in new plant construction include Arizona, Texas and Ohio.

We need to get in the game.

Leave a Reply

You must be logged in to post a comment.