Jeanine’s Memes

Share this article

ADVERTISEMENT

(comments below)

ADVERTISEMENT

(comments below)

Comments

46 responses to “Jeanine’s Memes”

-

Not long🙁

-

With, or without, regulated brake inspections?

-

interesting article in that liberal rag RTD:

-

The GOOD news is that Norfolk’s economy took only a small hit so that Atlanta’s could take a real shellacking.

-

Not funny but needs to be posted, nonetheless…

-

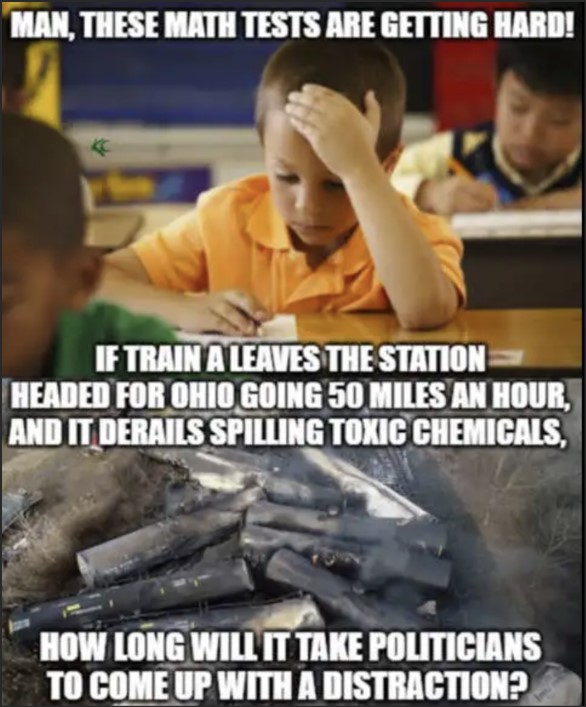

Fact check: The rules which would have required trains to have electronic brakes would not have applied to this train.

Verdict: FALSE. Picture of derailment in East Palestine, OH.

-

Saying that braking regulations would have prevented this derailment is like saying that ABS will keep your car from crashing when a wheel comes off.

-

Hey, I said you were right, the regulations on highly hazardous train braking systems that Trump slashed would not have stopped this derailment – I feel safer knowing that…

-

Even if they had applied to this train it wouldn’t have helped. The wheel locked up or came completely off; either way a derailment was inevitable. That was due to an overheated bearing, which according to surveillance video was on fire nearly 20 miles before the derailment.

The preliminary NTSB report says that the hotbox detector the train passed through prior to the derailment did not report a high enough temperature for the crew to take action. It seems to me that if the bearing were shooting flames it should certainly have been hot enough for the detector to report a high enough temperature for action to be taken, perhaps the hotbox detector wasn’t working correctly. Maybe it stores the temperature as an 8-bit integer and it overflowed.

-

Actually if the braking system were in place, fewer cars would have derailed – a much smaller impact to be sure.

-

Show me the evidence for that.

-

‘Asked if ECP brakes would have made a difference in East Palestine, Ditmeyer said: “There would not have been that huge pile up of cars coming from the rear that piled and caused ruptures and fires. So, yes, there is a very high likelihood that there would be significantly less damage.”’

https://www.wtae.com/amp/article/east-palestine-derailment-electronic-brakes-dot/43013996

-

-

-

-

Aside from the fact that it wouldn’t have prevented this disaster..why didn’t the Biden administration reinstitute that rule?

We’re now into the 3rd year of the Biden administration, when does it start to take some responsibility for what’s going on instead of blaming Trump for everything???

-

It does tend to take a bit more effort to enact new regulations than repeal them… but a good question…

-

-

All the electronic brakes in the world aren’t going to keep 2 miles of slack coming in, which generally is the cause of the derailment.

As I’m sure you’re aware unless that car bares the name of the railroad, it’s maintenance is up to the entity for whom the railroad is shipping it. If they failed to conduct proper maintenance to include that bearing, they’ll be on the hook with NS for the legal settlements.

The kicker about being a railroad is, it’s unlimited liability. So they will be sued now until the Lord comes back and keep paying out that money.

-

Do they (NS) require proof of a current inspection of a car owned by someone else before putting it behind their locomotives? (I read elsewhere that these cars are supposed to be inspected every 3500 miles. Since I’ve never seen a hub-odo-meter like you see on trailers on a railcar, I wonder how they keep track of that mileage).

-

Never worked rolling stock, however I’d presume they know the distance to and from where they are shipping and should be able to track that. Yes, as far as I’m aware the contract stipulates the car must be inspected for working order.

Granted some entities don’t care, I can’t count how many cars with sugar on their wheels caused detruckings or derailments in my class yard.

I also take people whom clamor about regulations without knowing the process with a grain of salt. He’s parroting a party talking point, hea never had the ability to speak for himself.

CFR and FRA govern class I’s just fine.

-

If we did rail like we do other industries including automobiles, we’d mandate the sensors and it would be up to the rail companies to find the least costly methods.

Without the mandate, they will not expend money on it.

not rocket science.

-

Are defect detectors mandated by law? If so is there a minimum spacing? Should more advanced thermal imaging be mandated? (I’m guessing that they aren’t using a FLIR-type thermal camera).

-

I dunno. I just think safety regulation for cars and other consumer products is done differently than industries like the rails.

Like most cars have sealed bearings that last for the life of the car usually and did not used to be that way. Now they are sealed and built to specs that make them long lasting.

Is it impossible to do something like that for rail?

The current approach to have trackside detectors doesn’t seem like a bad idea in and of itself – but the question is how does the trackside sensor commnicate with the train engineer. Is he/she getting realtime info? If he is and we’re still getting wheelbearings overheating and derailing something is not working and apparently failure of wheel bearings is an “ok” thing with the rail industry.

-

Do not know the answer about wheel bearings. But even sealed bearings in vehicles can fail long before the car is ready for the scrapyard. My suspicion is that the shock impact of hitting a pothole dooms them to an early death.

Another thing to consider–railcars seem to have a MUCH longer life than cars. At least based on what I’ve seen in NTSB reports–sometimes these railcars are 30 years old and have who knows how many hundreds of thousands of miles on them.

I can answer your last question. The trackside sensor is connected to a radio transmitter and an automated voice tells the engineer what’s going on.

It might say something like:

“Norfolk Southern defect detector milepost 110.3. 124 axles, no defects”.

You can actually hear these with a radio scanner.

https://www.youtube.com/watch?v=7SVynE6DCdo&ab_channel=V12Productions

-

It seems pretty rare to hear of a wheel bearing failure on autos these days. Back in the day, they had to be lubed on a regular basis. Still works that way for travel trailers… many have to be done every year, apparently sealed units are way too expensive.

On the detection. Does it say which car has a problem or only that a car in the 127 car unit , somewhere has a problem? Beyond that, what is supposed to happen? Is the train supposed

to stop and wait for repair or keep going until? -

It does say which axle number has a problem, and from the axle number the crew is able to determine which car it is.

I think the crew is supposed to call dispatch for further instructions if a defect is detected. But I am not sure on that. The alternative is that they stop, then call dispatch for further instructions. They are definitely not supposed to ignore it and keep going.

-

If they stop, doesn’t it screw up the other trains operations and schedules? Don’t they have to

get off the mainlines? -

Probably yes, but the alternative is to keep going and if they do that, they’re going to be stopping eventually anyway, when the train derails.

They have to stop the train when the crew runs out of hours, and as often as that happens, it doesn’t seem to be a big deal, even when the train is blocking a crossing for hours.

-

right. so they keep going because they can’t stop on the mainline without screwing up the

other trains.Doesn’t sound like there is a reasonable way to deal with a bearing coming apart on a train

other than keep going.. until…Do the even have a way to get to the train on a siding to deal with the bearing so the train

can then proceed?I’m betting it’s a bit of a conundrum and probably one of THE primary reasons for derailments.

And I’m betting this is not something they never knew before.

-

No.. You stop the train as soon as you have an indication of a bearing problem.

The time and expense of dealing with a failed bearing is a LOT less than the time and expense of a derailment (which will shut down BOTH tracks if a double-track).

The automotive equivalent might be driving on a blown tire rather than stopping and calling for road service. Drive on a blown tire long enough, and not only will you have to replace the tire, you’ll have to replace the wheel too.

Or driving with the engine coolant temp gauge in the red, or the oil pressure warning light on. You can either stop while the engine’s still running or stop when it decides to lock up.

Either way, you’re gonna stop. Either the hard way or the easy way.

-

You’re right on the logic but I don’t think they stop the trains and screw up schedules either.

I’ve seen what happens when VRE or CSX runs over a wayward person on the tracks… The

impacts to the train system can be regional, right? -

The schedule is getting screwed up one way or another if an overheated bearing is involved.

Also, freight trains typically don’t operate on schedules like passenger trains do, which is probably why I’ve NEVER seen an Amtrak blocking a crossing for hours.

-

okay. But both freight and passenger have dozens, hundreds of trains en route on tracks in

real time. If one stops, all the others on that line behind that one are affected and, in turn

all the units behind them, etc, etc.. right? It’s a complicated dance to keep them all moving

without running into each other. Some have to hit the sidings at precise times or else. -

If a train is stopped and there’s dual track they can and do route a train that needs to pass it onto the empty track. For single track they have passing sidings.

If you’re trying to suggest that a RR would intentionally ignore a failed bearing to keep the train on schedule..I would say that depends on whether the RR has an idiot making that decision, because the idiotic decision would be to do exactly that.

-

but we do have derailments all the time? 1000 or so, not all due to bearings?

-

Derailments can happen for a number of reasons, such as track problems or a switch that isn’t lined up correctly (in fact there’s been a few cases of people tampering with switches and causing a derailment). Not always caused by a bearing.

-

seems like where they do have detectors, there ought to be sidings to pull off if one is “hot”? Are there a lot of detectors or only a few?

-

What I read is that NS puts defect detectors about every 10 miles. I do not know if this is an industry standard. Looking at aerial views of NS trackage in Virginia, I don’t see many sidings and the siding would need to be long enough to fit the entire train. As you may know, trains have been getting longer as of the last few years due to industry changes.

I suspect that dual track pretty much eliminates the need for a siding–crossovers on dual track seem to be quite frequent on NS tracks I’ve looked at on aerial views.

-

so in some places, even if they know, they could not get off and stopping on the mainline not an option either unless they derail…..

I don’t blame them. Everything is a calculated risk and a judgement and probably no one more knowledgeable about tradeoffs than folks who do the work.

-

I would say that stopping on the mainline to avoid a derailment is not only an option, it is a requirement.

-

you think that’s an engineer call or higher up?

-

Engineer is closest to the problem and has the most info about it. Should be the engineer’s call.

-

but he can’t stop without calling in, right?

-

Sure he can. There’s no danger of another train crashing into them. If a train stops for any reason, the block signaling system will prevent a following train from crashing into them because the signals will be showing a “stop” aspect (usually red). And because a train takes a while to stop, the signals further away (perhaps miles further away) will show indications telling the train to slow down and prepare to stop at the next signal.

Only one train is allowed to occupy a block (a length of railroad; do not know how long the blocks typically are, maybe a couple of miles?) at a given time.

It’s a failure of their block signaling system that caused WMATA Metro trains to crash into each other some years back. Metro’s problem was caused by improper application of impedance bonds–they used the wrong ones, apparently in an attempt to save money. All the details are in an NTSB report, which I did read.

(Impedance bonds are only used with elctrified track)

-

you seem to know “stuff” on this… 😉

-

I was one of those kids that took all of my toys apart to find out how they worked.

-

and has watched every “How it Works”? 😉

-

And Mr. Wizard before that!

-

-

The real schedule that I recall is where they share track with Slamtrak. Even when Slamtrak is operating on railroads tracks, to slow or stop them is a fine.

Leave a Reply

You must be logged in to post a comment.